How To Make A Bong: Step By Step

Love your bong? You'll love it even more once you learn all about the hard work that goes into crafting glass bongs, pipes, and bubblers. Keep reading to discover all there is to know about the delicate process of creating glass bongs.

Search for “how to make a bong” and you’ll find no shortage of tutorials on how to piece together makeshift pipes from household items such as plastic bottles, hoses, and even apples.

But even the best of these DIY pipes won’t stand up to a professionally crafted glass bong. So, if you’ve ever wondered what goes into making a proper bong, you’re in luck! In this article, we’ll walk you through the ins and outs of glass bong crafting, bestowed upon us by the legendary German glass manufacturer Thomas Ehle.

How to make a glass bong

Glass bongs are a staple in the toolkit of most cannabis lovers, and for good reason—by filtering smoke or vapor through water, bongs deliver cool, smooth, and flavour-packed hits. Their production, moreover, is nothing short of impressive.

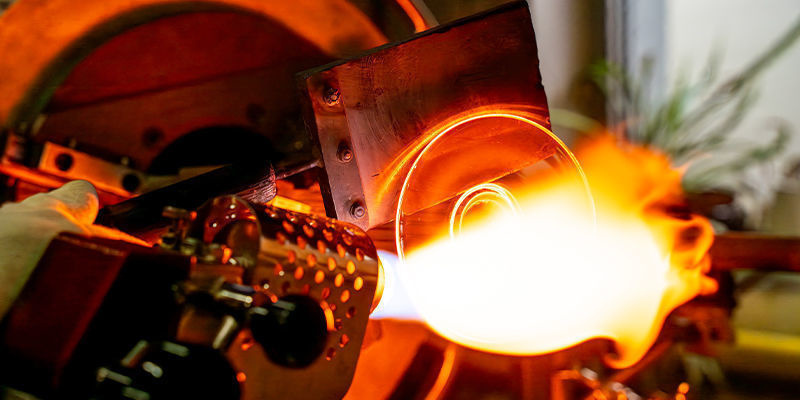

Glass bongs are crafted by experienced glassblowers who use fire furnaces or torches to heat glass to such high temperatures that it becomes malleable. Then, they’ll use blowpipes and other specialised tools to shape what used to be a plain cylinder of glass into a stunning and fully functional pipe.

Of course, the process of creating a glass bong may vary depending on the design of the pipe and the workflow of different glassblowers. In general, however, the process looks something like the following.

1. Picking the right materials

The first step to crafting an exceptional glass bong is picking the right material. And for glass bongs and pipes, which get regular use and are exposed to high temperatures, borosilicate glass is the way to go. Most smokers also prefer glass smoking accessories as they are tasteless, odour-free, and easy to clean in comparison to silicone pipes, for example.

Borosilicate glass, as its name suggests, is predominantly made up of silica dioxide and boron trioxide. Its composition gives it an extremely high melting point of about 1,650°C and also limits its rate of thermal expansion. In turn, borosilicate glass can handle extremely high temperature fluctuations without fracturing.

Besides being used to make bongs, borosilicate glass is also commonly used to make reagent bottles and laboratory equipment.

2. Cutting the glass

Borosilicate glass comes in tubes, which can be clear or coloured and of varying thicknesses. Once a glassblower has picked out the ideal type of glass for a pipe, they’ll calculate the amount needed and cut it from a borosilicate glass tube. To do this, they’ll first score the glass using a specialised glass cutter that deeply scores the glass’ surface. Then, they’ll apply some moisture to the score followed by some pressure to separate it from the rest of the tube.

3. Shaping the mouthpiece

While it might seem counterintuitive to some, professional glass blowers usually start their pipes from the mouthpiece, as it’s usually the smallest section of a pipe. Moreover, while smokers often pay more attention to a bong’s chambers and percolators, the mouthpiece is actually an extremely important part of the anatomy of a pipe, given that its size and shape directly impact the level of comfort and ease when smoking/dabbing.

To forge a mouthpiece, glass blowers will first heat the piece of glass they separated in Step 2 to around 650°C, rotating it continuously to ensure it heats evenly. Using special tools such as a graphite paddle, tweezers, pliers, and more, they’ll then start forging the thickened, round edge that you find on most bongs. They may also add flourishes to the mouthpiece, such as coloured dots or crowns, for extra flair.

4. Adding the twist

After forging the mouthpiece, glassblowers like Thomas Ehle will move on to forge the neck of a pipe. The simplest designs will just have a straight, cylindrical neck, but some may call for twists, bends, indents, ice notches, ribs, or glass dots. Not only do these details look great, but they serve an important purpose. Indents and ribs, for example, serve as ergonomic grips from which to hold a pipe, while ice notches (you guessed it) help to hold ice cubes in place. Twists or bends, on the other hand, help to alter the path of smoke/vapor as it travels from the base of the bong to the mouthpiece, promoting faster cooling for smoother, better-tasting hits.

5. Melting and shaping the chamber

When creating a bong with a round or beaker-shaped chamber, this is the stage where a glassblower will shape it. Of course, the exact process here will vary depending on the design of a pipe. Typically, glassblowers will shape a bong chamber by heating the glass using a torch (just like in Step 3), then blowing it using a blowpipe. They’ll then shape the chamber using paddles, tweezers, and pliers.

6. Melting and shaping the base

After crafting the mouthpiece and neck, glassblowers proceed to shape the base of their bongs. Again, the exact process here might vary depending on the design of a pipe—pipes with large spherical or beaker-shaped chambers, for example, will require different bases than a straight cylinder bong. Nonetheless, a good base is crucial for the proper design of any bong. After all, no one likes cleaning up spilled bong water, soggy weed, and glass shards—especially not while high.

7. Adding initials or other personalised logos/designs

Besides their excellent functionality, part of the fun of smoking through a bong comes from their unique designs. Logos, decals, glass marbles, or other similar elements are what turn a standard glass pipe into a personal artefact. Most glassblowers add these details to their pipes after crafting the mouthpiece, neck, chamber, and base.

8. Making the connection for the downstem/bowl

After elaborating their artwork, glassblowers will finish the main structure of their pipes by forging the downstem. Here, most glassblowers have their own special technique, and getting the procedure down pat takes time, experience, and the patience to potentially screw up a few pipes on the home stretch of making them. Nonetheless, learning how to forge a great, functional, and smooth-smoking downstem is essential for crafting a great bong.

9. Punching the carb hole

Carbs are a must-have for most serious bong smokers, as they regulate airflow into the pipe (which further helps to control the rate and heat at which your bowl burns). Some glassblowers will manually blow their carb holes, but Thomas Ehle and others punch them through the glass with a red-hot metal tip. The placing of a carb hole is super important, as it needs to be easy to access when smoking, so most professionals place them right on or beside a pipe’s main grip.

10. Sandblasting (optional)

Love the look and feel of a sandblasted bong? You’re definitely not alone—sandblasting glassware gives it a frosted appearance that’s very eye-catching while also improving grip. The simplest way to sandblast glass pipes is to use a blast cabinet, which creates an isolated environment that contains the mess of this process.

11. Flame polishing

After sandblasting, it’s time to polish a bong to give it a smooth, shiny surface. To do this, bong manufacturers rapidly pass their pipes under a flame. This causes the surface of the glass to melt very briefly, creating surface tension that makes for a smooth, clear, and shiny appearance. Flame polishing is used on all kinds of glassware, as well as thermoplastics, and is an important step in adding a professional finish to a product.

12. Signing and adding QR codes

Glass bongs and pipes are pieces of art and no less worthy of the artist’s signature than a painting or statue. That’s why Thomas Ehle and many other professional glassblowers finish off their designs with their signature. Moreover, some manufacturers add QR codes to their pipes that include warranty information, discounts, and more.

13. Annealing in the oven

The final step to creating the perfect glass bong is annealing. Here, bongs go into a kiln that heats the glass to temperatures of around 700°C. This process is extremely important as it relieves internal tension in the glass, keeping it from cracking in response to thermal or mechanical shock.

Bong-ing it all together

Glass bongs are a staple for smokers everywhere. And while their design might seem simple, the process that goes into forging quality glass pipes is long and delicate. In this article, we’ve walked you through the basics of how professional glass makers like Thomas Ehle and others craft their exceptional pieces. If you’re interested in crafting your own glass bong or pipe or learning more about glassware, look into glass workshops in your area.

-

4 min

15 March 2024

How To Find The Correct Joint Size For Your Bong

Understanding joint size is key to understanding what pieces of equipment your bong needs. Regardless of the shape and configuration of your bong, knowing the joint size will enable you to buy the...

4 min

15 March 2024

How To Find The Correct Joint Size For Your Bong

Understanding joint size is key to understanding what pieces of equipment your bong needs. Regardless of the shape and configuration of your bong, knowing the joint size will enable you to buy the...

-

6 min

5 September 2023

How To Use A Bong

Bongs might look threatening, but they're actually fairly easy to master (if you can get past the coughing). Learn all about how to use a bong here!

6 min

5 September 2023

How To Use A Bong

Bongs might look threatening, but they're actually fairly easy to master (if you can get past the coughing). Learn all about how to use a bong here!

-

5 min

23 May 2022

Top 10 Bong Accessories

Occasionally we can all get stuck in a rut when it comes to using a bong. Sometimes the enjoyment can fade a little, and the experience can all seem like a bit of a chore. Well, change that...

5 min

23 May 2022

Top 10 Bong Accessories

Occasionally we can all get stuck in a rut when it comes to using a bong. Sometimes the enjoyment can fade a little, and the experience can all seem like a bit of a chore. Well, change that...

-

6 min

21 October 2021

Top 10 Best Glass And Acrylic Bongs

Looking for a good bong? We can help! Here is our list of the 10 best glass bongs and acrylic bongs for every stoner's taste and budget!

6 min

21 October 2021

Top 10 Best Glass And Acrylic Bongs

Looking for a good bong? We can help! Here is our list of the 10 best glass bongs and acrylic bongs for every stoner's taste and budget!

United States

United States